- Pipe

- Bridges & Structures

- Walls

- Stormwater Management

- Erosion Control

- Start a Project

- Knowledge Center

- Technical Documents

The U.S. coastline is under attack! But not in the way many would assume; our coasts are under attack by the constantly changing environment, rise in sea level and increased severe-weather events. Although storms, floods and erosion have always been hazards, they now occur on top of higher sea levels. Combined with coastal development, these hazards now threaten approximately $1 trillion in real estate along U.S. coasts. According to the “2022 Sea Level Rise Technical Report,” the average global sea level rose around 10-12 inches during the last 100 years and is predicted to rise an additional 10-12 inches during the next 30 years. With more than 60,000 miles of U.S. roads and bridges in coastal floodplains, coastal designers will need to work fast to protect our valuable infrastructure.

When it comes to battling floods and sea level, one country stands out: the Netherlands. With about a third of the country sitting below sea level, the Dutch have become masters of controlling floodwaters and the impacts of the sea. One of the greatest Dutch accomplishments is the construction of the Afsluitdijk, a 20-mile dam and causeway. The Afsluitdijk was built in 1932 to close off the Zuiderzee (South Sea) to protect against flooding that was occurring due to storm surges. With a core of glacial till and armored by natural basalt columns, the dam had a height of approximately 26 feet above mean sea level, and the 3.5H:1V slope face was designed for 8-foot-high waves. During the last 90 years, however, the basalt columns have eroded and, coupled with increasing water levels and wave heights, led to the need to strengthen the Afsluitdijk. The rehabilitation included increasing the crest level to reduce the wave overtopping and reinforce the armor layer on both sides of the dam.

To strengthen the dam, the Rijkswaterstaat (the Dutch Ministry of Infrastructure and Water Management) desired to maintain the structure’s historic value and visual appearance. The rehabilitation contract included several unique aspects, including an approach that required the design to be adaptable for wave overtopping following actual sea-level rise.

The contract also motivated contractors to develop designs that would minimize new material use, minimize the use of the protected Wadden Sea area and maximize existing material reuse. Overall, the armor system would need to be placed in a regular pattern, the crest raised 6.6 feet and the dam designed for a significant wave height of 13.8 feet, a 68-percent increase. To meet the design requirements and provide an installation with lower carbon impact than the baseline concrete-cube reference design, a new concrete armor unit, XblocPlus, was developed.

New Armor Unit

The XblocPlus is a further improvement to the widely used single-layer armor unit, Xbloc. The XblocPlus offers high resilience to climate change, increased stability, low concrete consumption, fast and safe block placement, and reduced material quantities and CO2 emissions. These enhancements provide better economics with lower project lifecycle cost. In addition, placement on a regular grid simplifies installation and makes verification of installation much easier.

The XblocPlus shape can be described as a bird with a beak, a tail and two wings. Shape development focused on minimizing uplift pressures on the beak, using the wings to increase the distance between blocks, and creating gaps and openings to dissipate wave energy and reduce uplift pressures. Extensive numerical modeling was conducted using ANSYS CFD to study the velocities and wave pressures as well as the impact on variations in unit shapes. Each shape modification was tested in an 80-foot-long wave flume. In the final form, a hole was introduced in the center of the block. The hole greatly reduces the destabilizing forces and increases the hydraulic stability of the units.

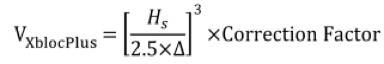

The stability of concrete armor units is defined by the stability number, Hs/ΔDn where the significant wave height is divided by the relative density times the nominal diameter. The significant wave height is the mean of the highest one-third of the waves at the toe of the structure.

In the physical model testing of XblocPlus, no extractions or rocking occurred—even during a 200-percent overload case. The XblocPlus units rest on the slope and on two units in the row below. They are further stabilized by two units in the row above. This above-and-below interaction interlocks the units. The large interlocking capacity of the units provides a design stability number of 2.5. While a higher stability number could have been selected based on the physical model testing, a value lower than other armor units was selected to provide more resilience and safety in design. When wave heights increase due to climate change, the XblocPlus system will have reserve capacity.

The XblocPlus system provides a visually smooth aesthetic appearance, however, the units have large open spaces, resulting in a large influence factor for roughness (γf). The roughness factor for XblocPlus units on a permeable core is 0.45.

Design of the Afsluitdijk

The design and crest level were originally determined using the 2018 EurOtop Manual (an overtopping manual based on European research). The required armor unit size for protection against wave attack is determined mainly by the design wave conditions. Additional considerations for project geometry, geotechnical parameters and water depth were used to ensure correct sizing of the units.

The recommended formula for determining the required volumetric unit size is shown in Equation 1. If more than one of the additional considerations for correction factors exist, then the largest value should be used as a starting point for physical model tests. Based on the wave height, the XblocPlus stability coefficient of 2.5, and project correction factors, an XblocPlus size of 6.6 U.S. tons was selected. To armor the new 2H:1V slope of the Afsluitdijk, eight rows of XblocPlus units are required with a total of approximately 75,000 units needed for the armoring. An artist rendering of the new Afsluitdijk protection system is shown in Figure 3.

A special feature of the Afsluitdijk design is the berm that lies approximately at the high-water level. This is very effective to reduce wave overtopping, but it poses a large challenge for the hydraulic stability of the top block on the lower slope: the wave loads are high at the water level, whereas the top block lacks the added stability that would be provided by blocks above. Therefore, a customized XblocPlus unit, the berm block, is applied at the top of the lower slope. This block is an XblocPlus unit with increased mass, weighing 12 U.S. tons instead of the normal 6.6 U.S. tons. The berm blocks also have extra voids to release the wave pressure between the units and the asphalt of the bicycle lane on the berm.

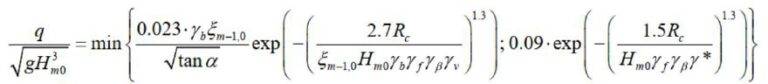

The average wave overtopping discharge can be predicted from Equation 2 (EurOtop 2018) where q = average overtopping discharge; Rc = freeboard; α = slope angle; ζm-1,0 = breakwater parameter; γb = the influence factor of the berm; γf = the influence factor for the roughness of the slope; γβ = the influence factor for oblique waves; and γv and γ* = influence factor for a wall on top of the slope.

With the composite slope of the Afsluitdijk, the roughness influence factor, γf, is difficult to predict as it depends upon the amount of wave overtopping and wave steepness. Therefore, physical modeling was needed to better estimate the overtopping.

Figure 4. A Berm blocks after installation (above) and after completion of the bicycle lane (below). Photos by Jan Wessels; courtesy Rijkswaterstaat & Levvel

Physical Model Tests

In coastal design, simplified methods are used to compute the hydraulic and structural performance of a coastal structure. Boundary conditions such as bathymetry, wave climate and available materials can vary from region to region, making each installation essentially unique. The further site conditions vary from boundary conditions, the larger the uncertainty and risk. Physical model tests are an important step in confirming and optimizing a design. In addition, they can provide more information in terms of overtopping.

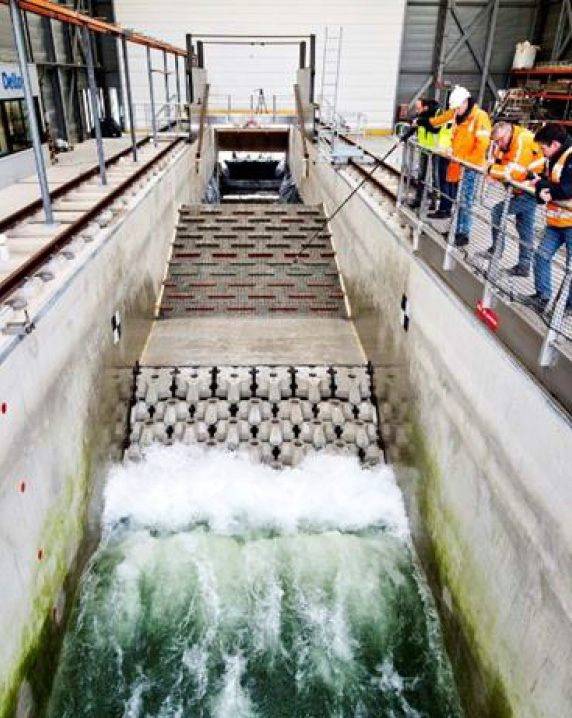

To prove that the XblocPlus units would meet project requirements, multiple-scale physical model tests were conducted. Initially, smaller-scale tests of 1:20 and 1:30 were conducted to optimize the design with regard to wave overtopping and armor stability. Finally, a one-third-scale (1:3) test was conducted in the Delta Flume of Deltares. The Delta Flume is one of the world’s largest flumes, with a width of 16.4 feet, a height of 31 feet and a length of almost 1,000 feet. Waves can be generated up to a maximum significant wave height of 7.2 feet, but the facility has produced a record individual wave of more than 15 feet.

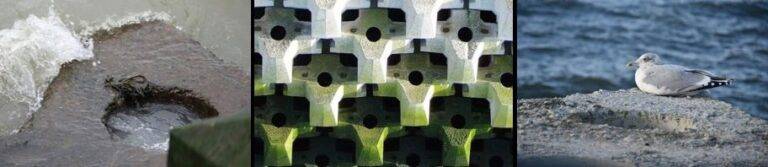

The larger scale was used because scale effects on tests of the stability of block revetments are negligible at smaller scales. Otherwise, there is the risk of conflict between the Reynolds scaling law for flow in the filter and the Froude scaling of the waves. In the testing for the Afsluitdijk, wave heights up to 5 feet were generated along with a 10-percent overload case. The hydraulic stability of the armor, underlayer and toe were monitored. Figure 5 shows a wave breaking on the XblocPlus units in the test facility.

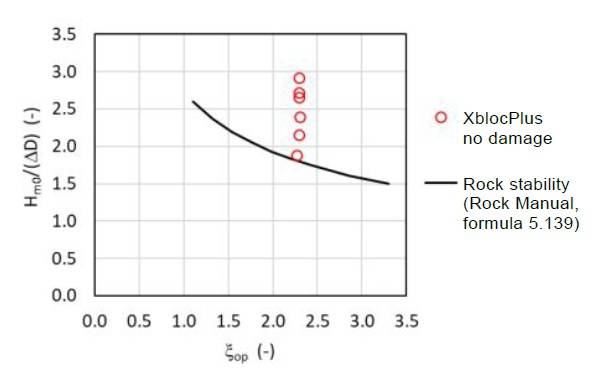

The XblocPlus units were very stable during all tests, confirming there is a significant safety factor included in the stability number of 2.5 as provided for design. The stability of the XblocPlus units is shown in Figure 6 along with a comparison of the stability of a rock slope calculated with the Van der Meer formula modified by Van Gent for a shallow foreshore (Rock Manual 2007). The figure shows that no damage occurred for an equivalent stability coefficient of 3.0. The interlocking of the XblocPlus units and their unique shape allow for this high stability to be achieved.

Comparing the wave overtopping measurements from the flume test with the estimates obtained from Equation 2 showed good alignment and within contractual requirements.

Resilience of Afsluitdijk Design

The design approach for the Afsluitdijk has built-in resilience to cope with uncertainty with regard to future water levels and wave climate. The XblocPlus layer on the lower slope was able to withstand substantially higher waves than the design conditions based on current predictions of future climate conditions. Therefore, there will be no need to strengthen the structure if the waves and/or water levels become more adverse than currently predicted. It may be necessary in that case to increase the crest level of the dike to reduce wave overtopping. Although this would still be a large operation, it is only a limited task in comparison to a full upgrade of the entire structure.

Environmental Considerations

With the XblocPlus armor layer located within the tidal zone and the units’ 60-percent porosity, they provide a habitat for marine life such as crabs, lobsters and shellfish. To further enhance marine growth, the top surface of The units was roughened, and two small tidal pools were added on top of the units.

Utilizing XblocPlus units instead of the concrete cubes from the reference design resulted in a 56-percent savings on CO2 footprint due to the comparatively thinner, more-porous armor layer. The blocks also lead to large CO2 savings compared to traditional rock armor solutions by reducing material quantities and transport emissions. Furthermore, the old existing basalt armor protection was removed from the dam and re-used as aggregate in the new XblocPlus units. This reduced the quantity of aggregate needed for the project and also helped reduce the impacts of disposing of existing materials.

As a test program to qualify future concrete enhancements, Rijkswaterstaat incorporated eight new sustainable concrete technologies. These eight mixtures were cast into 32 units to test the different technologies aimed at reducing CO2 emissions. The 32 test blocks will be routinely inspected for visual issues, durability, discoloration, crumbling, and bio-attachment. Mixtures that prove favorable will be allowed to be incorporated into future Rijkswaterstaat projects.

Installation

The XblocPlus units are placed on predefined coordinates. The placement grid is a half-brick bond, so each unit is placed between two units in the row below and then interlocked by two units placed above to gain stability from interlocking with the surrounding units on the slope. The hole in the XblocPlus units allows for hydrostatic pressure relief (increasing unit stability) and also doubles as a lifting point. A gripper is inserted into the hole in the top of the unit. This can be accomplished by an excavator operator without needing any ground-labor assistance, making the installation of XblocPlus units safer and more efficient.

For installation on the Afsluitdijk, a hydraulic crane floating on a barge on the seaside was utilized to place the units. The excavator used a hydraulic gripper with a rotator to provide full control of the placement. No labor was needed on the barge for connecting the XblocPlus units, nor on the ground at the installation point. In addition, the excavator was equipped with a screen providing a real-time 3D BIM model to allow for visualization of exactly where to place the units.

Conclusions

Building infrastructure today that will be strong enough to manage the extreme forces of tomorrow can be costly. What if, instead, technologies were used with built-in resiliency to meet short-term project goals and remain within their current budgets, and be resilient and adaptable for future changes? The XblocPlus armor system meets these objectives for coastal protection. The interlocking armor units have a high reserve hydraulic stability, which makes the XblocPlus units suitable for changing hydraulic boundary conditions due to climate change, rising sea levels and increasing severe weather events in breakwaters, jetties and shoreline projects around the world.

Authors

Daniel Priest, P.E., is the Hard Armor Solutions General Manager for Contech Engineered Solutions. He is a registered professional engineer with more than 20 years of experience in design and construction of geotechnical and hydraulic structures. He holds a B.S. in Civil and Environmental Engineering from the University of Cincinnati and an M.S. in Civil and Geotechnical Engineering from Northwestern University in Evanston, Ill.; email: [email protected].

Pieter Bakker is the Global Manager Xbloc for Delta Marine Consultants. He has an M.S. in Hydraulic Engineering from the Delft University of Technology. As a coastal specialist, he has worked on numerous coastal and port projects from small-scale marinas in Central America to large port developments in Europe, off-shore islands in the Middle East and hurricane protection systems in the United States; email [email protected].

Click on the button below to start the quiz for this course. Your score will be tabulated while you wait, and you will receive your certificate upon completion if you correctly answer eight or more questions.

Registration on v1-education.com is required to access the quiz. Use the "Sign Up" link in the top right of v1-education.com to register. If you are already registered simply enter your credentials to access the quiz.

The Professional Development Series is a unique opportunity to earn continuing education credit by reading specially focused, sponsored articles in Informed Infrastructure.

If you read the following article, display your understanding of the stated learning objectives, and follow the simple instructions, you can fulfill a portion of your continuing education requirements at no cost to you. This article also is available online at v1-education.com.

At the conclusion of this article, the reader should be able to understand:

Click on the button below to start the quiz for this course. Your score will be tabulated while you wait, and you will receive your certificate upon completion if you correctly answer eight or more questions.

Registration on v1-education.com is required to access the quiz. Use the "Sign Up" link in the top right of v1-education.com to register. If you are already registered simply enter your credentials to access the quiz.