- Pipe

- Bridges & Structures

- Walls

- Stormwater Management

- Erosion Control

- Start a Project

- Knowledge Center

- Technical Documents

The term “wildlife crossing” describes a variety of structures that are designed or retrofitted to provide safe passage for wildlife above or below a highway. Although wildlife crossing structures are not standardized designs, they can be categorized as two major types: overpasses and underpasses. Structures often are built in combination with fencing to increase their effectiveness.

Each crossing is designed to serve the target species for a specific location or accommodate the majority of species in an area. When wildlife crossing structures are designed for motorist safety, the target species typically are large ungulates such as moose, elk or deer. Other wildlife crossings are designed for species with high conservation concern, such as salamanders, desert tortoises, flying squirrels or kit foxes.

Throughout the United States, increased traffic volumes through areas with high animal populations often leads to increases in wildlife-vehicle collisions (WVCs). This not only affects wildlife mortality but also becomes a significant issue for motorist safety. With safety being the top objective for transportation agencies across the country, implementation of wildlife crossings has become a greater priority in the United States and especially in the West. Since 1990, U.S. overall traffic collisions have been reduced slightly, while WVCs have increased by roughly 5 percent per year, doubling from 1990 to 2008.

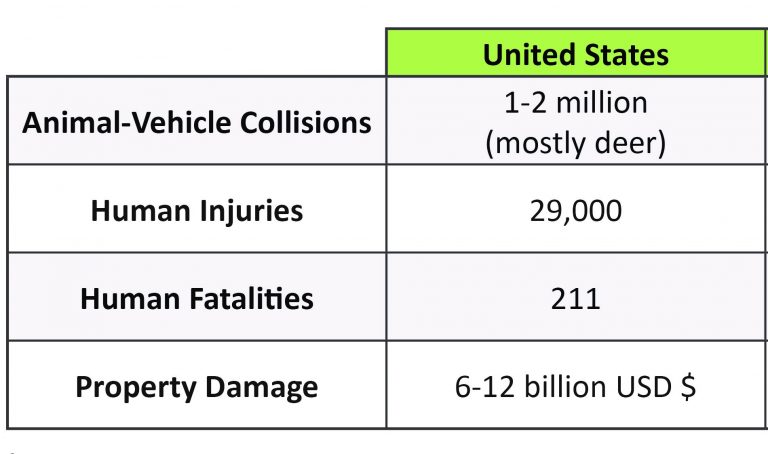

This increase in WVCs has significant associated costs in terms of human injuries, fatalities and property damage. Figure 1 provides some details regarding WVCs in the United States and their corresponding human injuries, fatalities and property damage costs.

In the last 20-30 years, the tracking of WVCs has improved greatly, but many incidents still are overlooked by official reporting techniques. For example, research by the Virginia Transportation Research Council recently reported that in their state, WVCs are six to eight times greater than what is reported by highway patrol records. This means that the actual amount of WVCs and their associated costs to U.S. taxpayers are much higher across the United States. The number of wildlife collisions is being tracked, to varying degrees, by many different entities (e.g., state departments of transportation (DOTs), state natural resource agencies, federal land management agencies, etc.). All are seeking to locate areas where certain animals need to move or migrate across the roadway. Collaboration of all these entities is needed to prioritize the locations for wildlife crossings.

The three species involved with most WVCs in the United States and have the largest associated costs per collision are deer, elk and moose. When assessing the cost per collision for each of these animals, consideration to human injury/fatalities, vehicle repairs, towing/accident investigation, hunting value, and carcass removal (see Figure 2) all are factors.

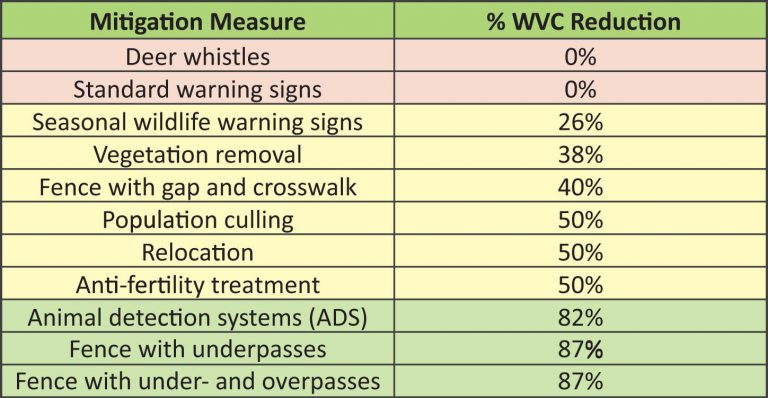

Most WVCs happen at a location that’s within a 100-yard section of roadway where animals (regardless of species) cross. This can be due to migratory patterns and the existing topography that gives them a pathway to cross. After a location is shown to have a high number of accidents with certain species, then the decision must be made on what type of mitigation efforts to implement with consideration to cost and best return on investment. Many different mitigation measures can be taken, from simply putting up warning signs to building a wildlife underpass/overpass and installing fencing. Figure 3 provides the percentage reduction of different mitigation measures that can be implemented to prevent wildlife collisions. The combination of fencing and an overpass or underpass provides the greatest reduction in collisions: 87 percent.

Wyoming Department of Transportation has seen a similar reduction in WVCs of greater than 80% after installation of the Trapper’s Point overpass on Hwy 191. A few years after the project’s completion, John Eddins, previous District 3 Engineer with WYDOT, commented about the WVC reduction, “There are not very many treatments a department of transportation can do to a highway to reduce crashes by 80 percent.”

High traffic volume can be a complete barrier to wildlife, impacting their biological needs. When wildlife habitats can’t be avoided near road corridors, a wildlife crossing will help mitigate the affected wildlife populations. Wildlife crossings also will reduce vehicle accidents that result in human fatalities, property damage and wildlife mortality. One in 20 of all reported motor-vehicle collisions are with wildlife, resulting in the leading cause of death and population declines for some mammals.

According to ARC (Animal Roadway Crossing) Solutions, an international nonprofit network whose mission is to identify and promote leading-edge solutions to improve human safety, wildlife mobility and long-term landscape connectivity, “A well-planned site strategy is critical to the success of a wildlife crossing structure. Because every mitigation plan is different, in order to identify cost savings, decision-makers must carefully consider various site elements in the planning process. This includes (but is not limited to): topography, road dimensions, vegetation, exposure and climatic conditions of the site, as well as the proper location of a planned crossing including impacts from human development, disturbance, and adjacent land use. In contrast to traditional highway infrastructure projects, planning transportation projects that involve and fully consider wildlife concerns poses unique challenges such as a need for collaboration across agencies and jurisdictional boundaries as well as coordination of funding schedules and agency missions.”

Wildlife Study and Crossing Data. The design team will need to determine the native wildlife connectivity needs combined with insight on possible future developments that could impact the functionality of a crossing. A wildlife study can be conducted to determine all of an area’s species and where they are crossing a section of roadway most often. This information is useful for selecting the two most-important aspects of a wildlife crossing: location and design. Key habitat linkages should be determined for the best locations that mitigate wildlife movement at an ecosystem level.

Wildlife crossing data from monitoring programs of existing wildlife crossing structures should be utilized to give an indication of what type of structures are effective for a given species. Size of structure opening for an underpass or width of an overpass also needs to be considered per species. In addition to the wildlife movement corridors, wildlife crossings should be placed where topographic features can be combined and utilized with the crossing structure.

Noise Load. Noise has been documented to affect different species to different degrees. Relative bird density will decrease significantly when noise load exceeds 40 dBA, so it’s sensible to design a wildlife crossing that has noise- and vibration-dampening characteristics. Tractor trailers can produce low frequencies that can travel large distances through solid objects. A buried bridge will provide maximum soil cover for sound dampening. Earthen sound barriers along with dense vegetation can be placed on the sides of an overpass to deflect road noise and light.

Topography.Streams, ridgelines and other dominant topographical features are ideal locations for a crossing. Microhabitat elements composing of local flora are beneficial to enhance wildlife movement when placed within the wildlife crossing. Place crossings in areas with minimal human disturbance. Enough native soil should be placed over the structure to retain moisture and support root crowns of the native flora. Avoid importation of soils from outside the project area.

The topography surrounding a roadway can be level, over a stream, sloped, below grade or raised. With a level site, the wildlife crossing can be raised with gentle slopes on the approach ramps. Lowering or raising the road grade also may be required to allow for an overpass or underpass. Road sections running perpendicular along a slope (cut-and-fill) can be problematic and may be too steep for a wildlife crossing. Roads below grade in cut sections are best suited for overpass structures, and raised road sections are ideal for underpass structures.

Structure Size and Placement. The FHWA recommends a wildlife overpass width to be 165 to 230 feet wide and an underpass to be greater than 40 feet wide by 15 feet in height. Structure length also should be taken into account when choosing an underpass, with larger openings for longer structures. A landscape bridge is an example of an overpass structure that will support all wildlife species but needs to be greater than 330 feet wide. A viaduct or flyover is an example of an underpass structure that will support all wildlife species. The length of the wildlife crossing should be less than 230 feet, and reducing noise levels is more important than regulating light levels because most crossings occur at night.

The most-suitable crossings for the greatest number of species are landscape bridges, wildlife overpasses, viaducts and wildlife underpasses. Fencing is a key part of mitigation that should be combined with the crossing structure to funnel wildlife through. Flared wingwalls will help wildlife locate and approach the crossing. Approach ramps should have a gentle slope of 5:1 or less, which, unfortunately, will drive up costs. Wildlife crossings can consist of, but are not limited to, concrete bottomless arches, structural plate, concrete or steel open-span bridges, and concrete box culverts.

Cost vs. Feasibility

Wildlife crossing structures—whether overpass or underpass structures—have shown to cost effectively reduce WVCs. However, these crossings have not been widely utilized due to their perceived or actual costs. To rationalize these crossings, transportation planners, engineers, biologists, ecologists and policy experts now are looking beyond standard transportation practices for unique cost-effective solutions that improve feasibility.

ARC Solutions recently compiled recommendations from industry experts to identify ways to reduce costs and increase deployment of wildlife crossing structures, where needed, while maintaining or improving their effectiveness. Their recommendations were broken down into three areas of potential cost savings: 1) planning; 2) design and construction; and 3) procurement, delivery method and cost-accounting considerations.

There are a number of items at the planning, design and construction stages that can significantly affect structure cost. The planning and design team should assess new materials, technologies and commercially available products or methods of construction. Location also should be considered when selecting structure type and construction methods, as wildlife crossings often are located in remote areas. Examples of elements that may be considered at the planning, design and construction stages include the following:

• Modular/Accelerated Bridge Construction (ABC). Modularity and ABC may reduce construction costs and disruption to the local traveling public.

• Use of a Buried Bridge may save costs compared to a Traditional Bridge.

• Foundation Costs. Selecting a structure that can tolerate more settlement may help reduce foundation size and costs.

• Geotechnical Evaluation. Upfront, early investigation of onsite soils will help drive the most cost-effective overall solution and avoid costly construction change orders post bid.

• End Treatments. Evaluate different wall types for cost and how they fit into the local site grading. Evaluate the need for end treatments with different slopes and grading.

• Specialty Equipment. Avoiding use of specialty equipment may reduce construction costs, especially in remote areas.

• Transportation Costs. Evaluate the origin of the construction materials or prefabricated elements, including the number of truck loads required and site accessibility.

• Local Sources for Backfill Material and Topsoil. If materials are not locally available, the cost of a structural solution may increase depending on the amount of critical backfill material needed.

• Onsite Supplier Expertise. Take advantage of supplier expertise, product knowledge and experience in building wildlife crossing structures.

A buried bridge can range from a smaller four-sided concrete box culvert or structural plate culvert to a larger three-sided concrete flat top, concrete arch or structural plate bridge. As ARC Solutions suggests, a buried bridge may have several advantages when utilized for wildlife crossings due to their ability to dampen sound and allow for ample cover over the structure for establishment of vegetation. However, these structures also have several structural advantages that allow for a more cost-effective wildlife crossing and improved cost-to-benefit ratio.

There are several prefabricated buried bridge options that allow for quick, efficient design and are optimal for cover vs. trying to retrofit conventional bridges to carry significant soil dead load to promote a natural soil-vegetated crossing. Buried arch structures will carry dead load more efficiently due to soil structure interaction, and the arched topped structures will shed water from the soil cover, eliminating pooling of water over the top of a structure. Buried three-sided structures often can be supported on cost-effective spread foundations and have an open bottom that fits in well with either an overpass or underpass. The open bottom allows the structure to span over the roadway in an overpass crossing, while providing a natural soil bottom for an underpass crossing. Oftentimes, underpass structures utilizing a three-sided structure also will integrate drainage or a stream in the crossing.

Prefabricated structures typically are manufactured in a high-quality controlled environment, are modular and fit with FHWA ABC guidelines. ABC reduces construction costs and timing, minimizes disruption to the local traveling public, and increases construction site safety.

Buried Bridge Project Analysis

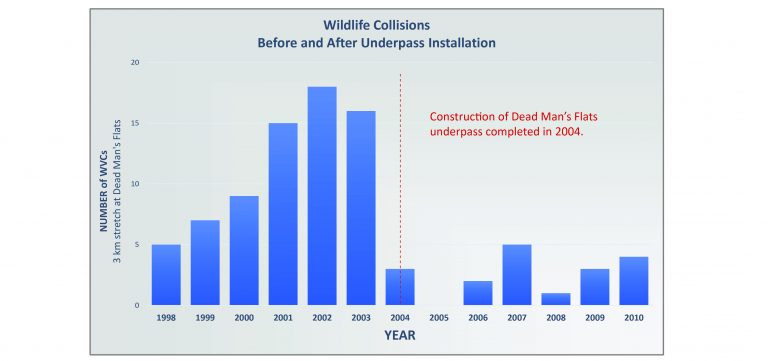

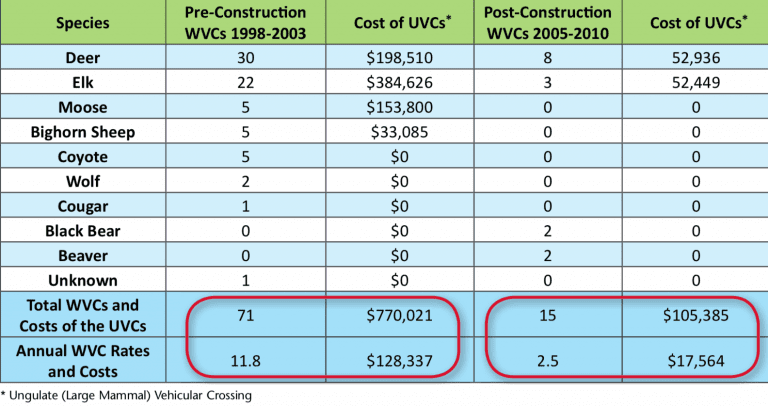

The Dead Man’s Flats project on the Trans-Canada Highway is a well-documented example of a successful wildlife crossing underpass with in-depth analysis. This three-kilometer (1.86-mile) stretch of highway was a hotspot for WVCs, and an underpass with fencing was installed. Figure 6 is a chart of the accidents on this stretch of highway prior to 2004 when the job was constructed as well as the five years after installation.

In the three years prior to constructing the underpass, WVCs averaged 17.5 per year, compared to an average of less than five per year post construction. When evaluating the cost five years prior and post construction, this reduction in WVCs amounts to roughly $664,636 in savings ($110,773 per year). So in less than five years, the construction project paid for itself, with the average underpass installation cost being $525,000.

Conclusion

Each wildlife crossing project is unique with many additional factors for consideration relative to a standard transportation crossing. Each year, more wildlife crossings are successfully being implemented and provide justification for future crossings. These structures are proven to reduce accidents and improve public safety, benefit the environment by protecting wildlife and also be a cost-effective solution.

References

• ARC Solutions, 2017, “Highway crossing structures for wildlife: Benefits of a national commitment to increase driver and animal safety,” ARC Special Publication No. 1(1), pp. 20; arc-solutions.org/arc-special-publications.

• ARC Solutions, 2017, “Innovative strategies to reduce the cost of wildlife overpasses, ARC Special Publication No. 1(1), pp. 20; arc-solutions.org/arc-special-publications.

• Donaldson, Bridget M., 2017, “Virginia Transportation Research Council Improving Animal-Vehicle Collision Data for the Strategic Application of Mitigation.”

• Huijser, M.P.; A. Kociolek; P. McGowen; A. Hardy; A.P. Clevenger; R. Ament, 2007b, “Wildlife-Vehicle Collision and Crossing Mitigation Measures and Associated Costs and Benefits: a Toolbox for the Montana Department of Transportation,” FHWA/MT-07-002/8117-34, Montana Department of Transportation, Helena, Mont.; www.mdt.mt.gov/research/projects/env/wildlife_crossing_mitigation.shtml.

• Huijser, M.P.; P. McGowen; J. Fuller; A. Hardy; A. Kociolek; A.P. Clevenger; D. Smith; R.J. Ament, 2008, “Wildlife-vehicle collision reduction study,” Report to Congress, U.S. Department of Transportation, Federal Highway Administration, Washington D.C.; https://www.fhwa.dot.gov/publications/research/safety/08034/08034.pdf.

• Huijser, M.P.; P. McGowen; J. Fuller; A. Hardy; A. Kociolek; A.P. Clevenger; D. Smith; R. Ament, 2007c, “Wildlife-vehicle collision reduction study,” Report to Congress, U.S. Department of Transportation, Federal Highway Administration; www.wti.montana.edu/RoadEcology/documents/Wildlife_Vehicle_Collision_Reduction.pdf.

• Lee, T.; A.P. Clevenger; R.J. Ament, 2012, “Highway wildlife mitigation opportunities for the TransCanada Highway in the Bow Valley,” Report to Alberta Ecotrust Foundation, Calgary, Alberta; www.rockies.ca/project_info/Bow%20Valley%20Highway%20Mitigation_FINAL_Sept2012.pdf.

• Vanlaar et al, 2012a, “Wildlife-Vehicle Collisions in Canada: A Review of the Literature and a Compendium of Existing Data Sources”; tirf.ca/wpcontent/uploads/2017/01/WildlifeVehicle_Collision_Deliverable1_Eng_6.pdf.

Timothy Miller is the Contech Engineered Solutions Structures Area Manager for Montana, Wyoming, North Dakota, South Dakota and Colorado. He graduated from the Colorado School of Mines and has worked for Contech for eight years. Miller has been involved with multiple wildlife crossing projects across Wyoming, Colorado, Montana and North Dakota, helping DOTs bring the projects to completion by evaluating options, sharing best practices from projects in other states, and collaborating with public/private partnerships to help fund the jobs; email: [email protected].

Michael Jambor is a Contech Engineered Solutions Bridge Consultant with more than 20 years of experience providing options and support to the engineering, owner and contractor community throughout the United States. He graduated from The Ohio State University with a B.S. in Civil Engineering; email: [email protected].

Daniel Wasniak, P.E., is the National Director of Precast Bridge for Contech Engineered Solutions. He graduated from Ohio University with a Bachelor and Master of Science in Civil Engineering as well as an MBA from Indiana University. Wasniak has 20 years of experience with buried bridges and has been extensively involved in wildlife crossings across the West; email: [email protected].

Online quiz for this article is not active and

PDH credit is no longer available.

This article is being maintained for informational purposes only.